BrandonTKZ

Member

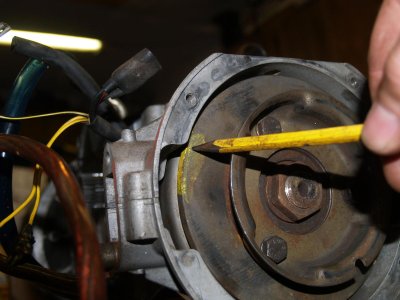

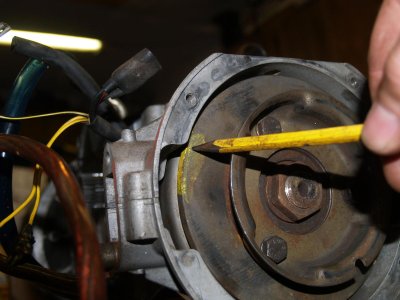

Hi Im currently doing a top end on my 583 that i got and i was looking at the timing while I have it apart and it doesn't make much sense to me. When the MAG connecting rod is at tdc the rotary valve lines up with the mark on the case like it should but the timing mark is like 1/4 rotation away. shouldn't the timing mark be on the 0 degree mark when the mag piston is at tdc? the first picture is when the mark is at 0 degrees