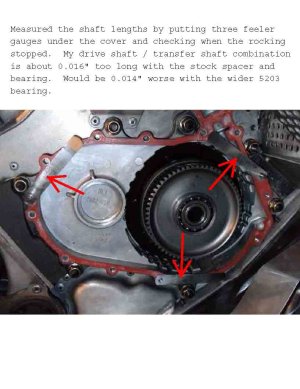

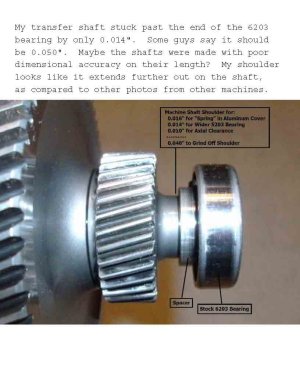

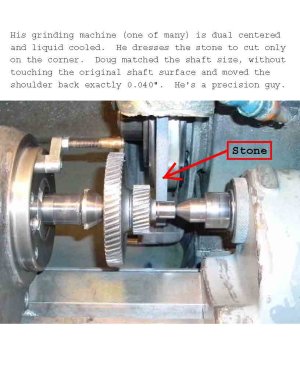

Thanks for the info. I also read if you go to the 5203 you have to grind some shaft down a bit to make up for the larger bearing size. If the 3203 is the same size as the 5203 I am assuming you would have to machine the shaft down as well?

Also, in the diagram above which bearing is it?

Part 14 above. Cat made an updated thinner spacer (part 13) for this application that addressed the need to machine the shaft and eliminate any potential axial load that causes the issue. I've seen it for 3000 kms with my own eyes and its taken miles of BC mountain abuse with a tall lug track and no grease issue due to RPM speed on the bearing as claimed. I take mine apart once a season and the bearing is like new and even still have the new bearings in my parts bins because I thought I would need to change them by now, but they spin so clean its ridiculous. Had my dad inspect the tolerances to confirm and no issues (42 year retired machinist but you can argue with his findings if you want).