You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ski Doo xm 800 turbo with powderfreaks head

- Thread starter kingcat162

- Start date

kfaz123

Active member

So you've got a Tra 3? With adjustable ramps? U lost me sorry

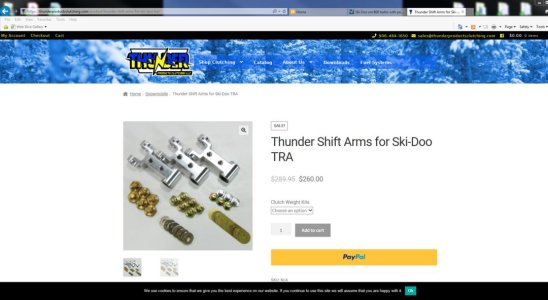

stock tra 7 clutch. stock secondary. i run dj`s mountain ramps in my primary with the adjustable thunder shift arms with my setup for weigh on the arms from a lot of testing. 160/320 spring in the primary and 2mm oversized rollers. i run dj`s helix in the secondary with djs secondary spring from dalton with hi torque rollers

- Thread starter

- #23

kingcat162

Active VIP Member

Sorry I was scrolling up and looking for the name of the arm but couldn't find it - do they come with instructions? Did you load up the base of the arm with heavy weight to get more load in the midrange?google dude... I found the thundershift adjustable arms in literally 1 second...

- Thread starter

- #24

kingcat162

Active VIP Member

I thought the stock primary was a TRA3? It's a TRA7?stock tra 7 clutch. stock secondary. i run dj`s mountain ramps in my primary with the adjustable thunder shift arms with my setup for weigh on the arms from a lot of testing. 160/320 spring in the primary and 2mm oversized rollers. i run dj`s helix in the secondary with djs secondary spring from dalton with hi torque rollers

kfaz123

Active member

I thought the stock primary was a TRA3? It's a TRA7?

Tra 7. Tra 3 is from way back. Top where the pin goes with the roller does top end rpm but also effects all areas but mostly top. next hole down does mid range rpm and bottom hole next to the lever axle that mounts the arm to the clutch does bottom end rpm. there is some overlap between areas obviously. yes they come with instructions but they are kinda vague but give you the idea of how the arms work and that should be all you need. you have to figure out what works with your setup as no 2 sleds and or turbo kits from different manufactures are gonna run the same or come into boost the same. impulse comes on early and very hard as im running a ball bearing gtx2860r with tial stainless exhaust housing and tial external waste gate. i had to actually buy their heavier extra weights for my mid range setup as the ones in the kit were not heavy enough. i did some testing with heavier bottom end weighting and it was pretty mental the sled was always in boost and launched so hard but it was hard to stop it from chopping holes in the trees when picking through deep powder slowly so i backed the weight off in the bottom end. so i can pick my way through the trees in the deep pow without trenching unless i wanna trench and make my buddies lives hard

Last edited:

- Thread starter

- #27

kingcat162

Active VIP Member

Wish I woulda had all this info yrs ago lol been struggling with this thing for 5 yrsJoined 7 years ago and you drop all this in 16 posts lol

Love it

kfaz123

Active member

Wish I woulda had all this info yrs ago lol been struggling with this thing for 5 yrs

no one shares this i had to figure it all out myself too. did so much reading back in the day with very little luck. lotta testing went into getting this thing dialed the way i wanted. im also very picky on the way my **** runs. so you make one change and you go test see if you made a positive improvement or not then make another change cant make to many changes at once cause you dont know what you did right or wrong to get there. i haven`t touched my clutching in years now. though i do have a hard time leaving well enough alone cause i always have in the back of my mind can i make it a little better lol. sled gets a new primary spring and bushings every year and new secondary spring and a new belt and i run it. other than any other maintenance that comes up i dont like break downs in season so im pretty heavy on the preventive maintenance but that's just me.

kingcat162 who`s turbo kit are you running?

- Thread starter

- #29

kingcat162

Active VIP Member

TSS centre mount with a redline box - Water to air - I have been going completely the opposite way with my clutching and gearing trying to figure it out - 174" 2.54 ratio - 160/260 spring - dj with 2mm rollers and dj sec helix and spring - empty pin weightno one shares this i had to figure it all out myself too. did so much reading back in the day with very little luck. lotta testing went into getting this thing dialed the way i wanted. im also very picky on the way my **** runs. so you make one change and you go test see if you made a positive improvement or not then make another change cant make to many changes at once cause you dont know what you did right or wrong to get there. i haven`t touched my clutching in years now. though i do have a hard time leaving well enough alone cause i always have in the back of my mind can i make it a little better lol. sled gets a new primary spring and bushings every year and new secondary spring and a new belt and i run it. other than any other maintenance that comes up i dont like break downs in season so im pretty heavy on the preventive maintenance but that's just me.

kingcat162 who`s turbo kit are you running?

kfaz123

Active member

TSS centre mount with a redline box - Water to air - I have been going completely the opposite way with my clutching and gearing trying to figure it out - 174" 2.54 ratio - 160/260 spring - dj with 2mm rollers and dj sec helix and spring - empty pin weight

yeah that's so far off being that light on pin weight. no wonder you blowing more reed cages than a hooker in a back alley. way to light pin weight. turbos need load not only to help control your rpm but load makes heat and heat spools turbos so the more load you have the sooner and harder your turbo will come in. yeah i mean you not wrong by running a 260 finish rate cause the more you lower you finish rate the more it loads the engine just like adding more pin weight but at some point you end up with so much pin weight to load the mid range correctly that you find on a long WOT pull you will hit 7900 rpm and then your rpms with drag down to like 7800 or 7700 rpm so you end up have to increase final force of your primary spring to get you rpms to hold at 7900 and not drop or at least this is what happened with my sled thats why i ended up with a 320 finish on my primary spring.

i also dont have a inter cooler on my setup i have a foot of charge pipe if that so there is not much pipe to have to build boost in this contributes to the sled coming on so hard. not that a inter cooler is a bad thing but i have a hood exit intake for my turbo so your sucking in -10 air by the time you boost it up to 8psi intake charge temps are only 70f so no need for it. now if your gonna run 14psi sure a inter cooler is smart because you will have high charge air temps. but you wont have a 800 etec living long at 14psi. 800 etecs with good fueling and clutching seem to last at 7 to 8 psi anymore than that and your on borrowed time. im still on my original motor at 7000kms

ive heard good things about the redline box. ive heard a lot of the center mount turbos from tss burnt down though. ive never looked at one first hand to see why that is and i dunno if its a pipe pressure issue or not. generally you want you pipe pressure to be 3psi above your boost pressure at all times. or if it was their fueling setup they had. though boost it kits always ran well.

also every time you gear down like you have you will have to run even more pin weight to compensate for the fact the sled will accelerate quicker because its geared down. i used to run 2.23:1 gear when i first was figuring everything out but i wanted the sled to be more rippy so i went to 2.33:1 but ended up having to add more mid range weight after cause i was starting to have issues with rpm rate of increase again

Last edited:

- Thread starter

- #31

kingcat162

Active VIP Member

5000kms on original motor - 3 sets of stock cages folded - 1 set of carbons inhaled - I feel like I'm going to be alot closer to being dialed in now learning all this from you that I was going completely the wrong way with my clutching - gonna order the arms tomm with the extra weight for mid - the centre mount also has a very short charge tube - also a Garret 2860r ceramic - external turbo smart waste gate with manual adjust - Reed installed in airbox - a long list of modsyeah that's so far off being that light on pin weight. no wonder you blowing more reed cages than a hooker in a back alley. way to light pin weight. turbos need load not only to help control your rpm but load makes heat and heat spools turbos so the more load you have the sooner and harder your turbo will come in. yeah i mean you not wrong by running a 260 finish rate cause the more you lower you finish rate the more it loads the engine just like adding more pin weight but at some point you end up with so much pin weight to load the mid range correctly that you find on a long WOT pull you will hit 7900 rpm and then your rpms with drag down to like 7800 or 7700 rpm so you end up have to increase final force of your primary spring to get you rpms to hold at 7900 and not drop or at least this is what happened with my sled thats why i ended up with a 320 finish on my primary spring.

i also dont have a inter cooler on my setup i have a foot of charge pipe if that so there is not much pipe to have to build boost in this contributes to the sled coming on so hard. not that a inter cooler is a bad thing but i have a hood exit intake for my turbo so your sucking in -10 air by the time you boost it up to 8psi intake charge temps are only 70f so no need for it. now if your gonna run 14psi sure a inter cooler is smart because you will have high charge air temps. but you wont have a 800 etec living long at 14psi. 800 etecs with good fueling and clutching seem to last at 7 to 8 psi anymore than that and your on borrowed time. im still on my original motor at 7000kms

ive heard good things about the redline box. ive heard a lot of the center mount turbos from tss burnt down though. ive never looked at one first hand to see why that is and i dunno if its a pipe pressure issue or not. generally you want you pipe pressure to be 3psi above your boost pressure at all times. or if it was their fueling setup they had. though boost it kits always ran well.

also every time you gear down like you have you will have to run even more pin weight to compensate for the fact the sled will accelerate quicker because its geared down. i used to run 2.23:1 gear when i first was figuring everything out but i wanted the sled to be more rippy so i went to 2.33:1 but ended up having to add more mid range weight after cause i was starting to have issues with rpm rate of increase again

kfaz123

Active member

5000kms on original motor - 3 sets of stock cages folded - 1 set of carbons inhaled - I feel like I'm going to be alot closer to being dialed in now learning all this from you that I was going completely the wrong way with my clutching - gonna order the arms tomm with the extra weight for mid - the centre mount also has a very short charge tube - also a Garret 2860r ceramic - external turbo smart waste gate with manual adjust - Reed installed in airbox - a long list of mods

oh right its water to air. intercooler is in the air box. i had air to air like a car in my head for some reason i dunno why. yeah i mean you wont have it dialed over night it will take some testing and rides to get it right but its more than do able and when you do get it right man on man its a nice feeling.

hmm i`ve actually contemplated doing the reed valves in the side of the air box to get more air in on the bottom end as the turbo is definitely a slight restriction before it hits boost. but looking over the new 850 factory turbo it would seem they are using the air by pass but it looks like they are also opening the electric waste gate to by pass the turbo on the bottom end completely till they hit boost something we cant do very easily with out some work on our pressure actuated waste gates

hows the reed cage in the side of the air box working for you? did you notice quite a difference with this mod. as im setup with my own tig welder so i could do this easily and have a extra reed cage kicking around

i also run the factory rave valve setup with the factory check valve manifold just sealed up better than factory with a secondary check valve inline as the white manifold tends to bleed off vacuum if you have ever bench tested one. they obviously do this when you back fire through them messing them up. but even brand new they dont hold vacuum completely and this is why i ended up with a second inline check valve on the vacuum side that seals completely

Last edited:

- Thread starter

- #33

kingcat162

Active VIP Member

I can't honestly say if the Reed in the airbox is working because I don't think honestly I've had it dialed in 100% there has been lots of times I have thought to myself that it's dialed in - to turn out it's not - I ran the raves off of the throttle bodies - seems to work good - I'm trying a Reed mod next because I'm done with the stock 2 piece cage - I keep bending them in the middle (turbo petals)then it lets too much air in and won't idle and run rightoh right its water to air. intercooler is in the air box. i had air to air like a car in my head for some reason i dunno why. yeah i mean you wont have it dialed over night it will take some testing and rides to get it right but its more than do able and when you do get it right man on man its a nice feeling.

hmm i`ve actually contemplated doing the reed valves in the side of the air box to get more air in on the bottom end as the turbo is definitely a slight restriction before it hits boost. but looking over the new 850 factory turbo it would seem they are using the air by pass but it looks like they are also opening the electric waste gate to by pass the turbo on the bottom end completely till they hit boost something we cant do very easily with out some work on our pressure actuated waste gates

hows the reed cage in the side of the air box working for you? did you notice quite a difference with this mod. as im setup with my own tig welder so i could do this easily and have a extra reed cage kicking around

i also run the factory rave valve setup with the factory check valve manifold just sealed up better than factory with a secondary check valve inline as the white manifold tends to bleed off vacuum if you have ever bench tested one. they obviously do this when you back fire through them messing them up. but even brand new they dont hold vacuum completely and this is why i ended up with a second inline check valve on the vacuum side that seals completely

kfaz123

Active member

I can't honestly say if the Reed in the airbox is working because I don't think honestly I've had it dialed in 100% there has been lots of times I have thought to myself that it's dialed in - to turn out it's not - I ran the raves off of the throttle bodies - seems to work good - I'm trying a Reed mod next because I'm done with the stock 2 piece cage - I keep bending them in the middle (turbo petals)then it lets too much air in and won't idle and run right

when i first ran the kit years ago i ran tdr turbo reeds but the bottom end sucked and i bent one reed cage slightly when i hit rate of increase to hard and had a huge back fire. tdr reeds were fine those things are indestructible but they are too stiff and don`t seal completely. once i figured out what i had to do with the clutching and got that dialed i`ve been running factory reed cages and reeds ever since great bottom end. never bent a reed cage never chewed a pedal yet. every year i check them thinking this will be he year one of these reeds finally chips but i`m still waiting lol

Last edited:

kfaz123

Active member

i would recommend getting your clutching right i doubt you will ever have a issue with reed cages again after you do

- Thread starter

- #36

kingcat162

Active VIP Member

So you just carve a set of petals in half and double em up like that?when i first ran the kit years ago i ran tdr turbo reeds but the bottom end sucked and i bent one reed cage slightly when i hit rate of increase to hard and had a huge back fire. tdr reeds were fine those things are indestructible but they are too stiff and don`t seal completely. once i figured out what i had to do with the clutching and got that dialed i`ve been running factory reed cages and reeds ever since great bottom end. never bent a reed cage never chewed a pedal yet. every year i check them thinking this will be he year one of these reeds finally chips but i`m still waiting lol

gofast89

Active member

Kingcat162 pm’d you

ctd

Active VIP Member

rate of rpm increase protection is there to try and protect your engine when you blow a belt, it retards ignition timing heavily to stop rpm increase so you dont twist a crank when your engine goes from being heavily loaded to unloaded when the belt leaves the building.r

No, this is not the reason the ECU is pissed off when the 800 E TEC accelerates to quickly. The Injector becomes unstable & it can go either "rich or lean". The ECU has control over timing, fuel & RAVE position. It will use which ever one of those or combination of to control the rate of acceleration. Nothing to do blowing belts or saving the crank.

You can have the same issue with a stock NA motor. Difficult to clutch the 800 E TEC because you have to work around the computer boosted or not.

Regardless a very good point that clutching needs to be correct with this motor, fuel control is another nightmare that most boxes can't cope with.....another 800 E TEC characteristic.

Your manually cycling your raves so that the boost pressure doesn’t shove them open?I can't honestly say if the Reed in the airbox is working because I don't think honestly I've had it dialed in 100% there has been lots of times I have thought to myself that it's dialed in - to turn out it's not - I ran the raves off of the throttle bodies - seems to work good - I'm trying a Reed mod next because I'm done with the stock 2 piece cage - I keep bending them in the middle (turbo petals)then it lets too much air in and won't idle and run right

Kingcat, I will second the info kfaz123 is giving. Totally mirrors my experience. Iv got a 2014 tss centre mount. First 1000km I had issues but looking back I totally believe it was all my own fault as I screwed with clutching. When machine was new, I rode pine pass Up north, not sicamous. Even with cooler temps and little lower elevation, I couldn’t get machine to get up to optimum rpm so I would drop pin weight. But in reality I was probably hitting rev limiter. Caused lots of backfiringK and I took out a motor at 800 km. Got clutching figured out. Iv got the tss Ramps, a spring from dalton (something like kfaz123 has 160/360, and about 23 gram pin weight. Set up can be sluggish on bottom end. I had not heard the the multi weight arms but makes total sense. My machine now has over 6000 km so current motor has over 5000 km on it with original pistons, reeds, and O2 sensor. Run 100% av gas. I still have the tss boost box and run 30% boost duty which translates to about 6 pds boost. If I ever need the sled to go on a local neibors hood Gallup I have a whole other clutch that I throw on. I believe I have about 27 grams pin weight in that one!!