ippielb

Active VIP Member

- Joined

- Mar 4, 2011

- Messages

- 1,967

- Reaction score

- 3,605

- Location

- SE Saskatchewan

- Website

- www.youtube.com

I think it would be helpful for people thinking about buying a sled deck, or have a sled deck that want to make life easier using and having one. Whatever it might be, changing the clearance lights, grommets for protecting your wires, deck boarding, tie downs, and so on.

I bought my sled deck used and a base model and did quite a bit to it since i've gotten it. Put on folding size extensions, all the lighting, welded seams, superglides, superclamps, supertracs, under deck lighting, grommets, wiring, and a winch.

First thing i do when putting the deck on, is make sure the deck is as far forward as possible, make sure it is safely forward as possible in other words it wont touch your back window when the truck flexes. If you deck has a headache rack, USE IT! Save your window and possibly the cab of your truck!

Second is if it's held down with turnbuckles, you tighten them in a crisscross pattern like the lug nuts of a car. Measure to make sure it's evenly spaced in your box from side to side. If your turnbuckles don't have jam nuts on them, put some on, set your tension, then tighten the jam nuts to hold the turnbuckle in place and prevent loosening.

If your deck has independent legs, like the Denali decks, it's well worth it to take some 2x4's cut them to length to tightly fit in between the front legs, and between the legs and the box. This will help with stress on the deck, and prevent cracking. I know it was a problem on some of the denali's and thats what i did with my old deck.

For clearance lights, i personally run LED's in everything. I won't run anything but. They last for ever, draw less amps, and don't run into heat problems. I run these 3/4" penny lights, i bought mine from princess auto for ease of getting new lights. If something does happen i can just go back and get another.

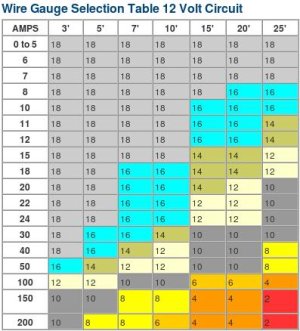

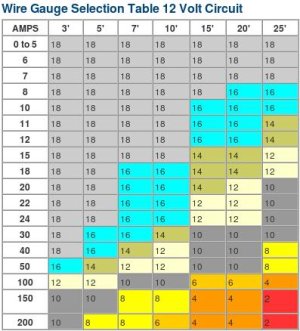

Wire gauge, this is something often over looked. If you are rewiring your deck, or building your own. Make sure you are running a large enough gauge of wire. You need to over estimate your distance, and over estimate your amp draw. Here's a table that will help you decide. Don't just get by on your wiring, it could burn down your whole truck.

For grommets, i run something totally different, i use 3/4" pipe end caps, everything on my deck is tubing, so i run my wires inside and hide them away keep everything neat and tidy. So i drill a 5/8" hole, and ram a 3/4" plug, drill out the center so my wire fits in it tight. These work great for thicker gauge steel or aluminum, and give a clean finish to the eye.

Your electrical wire needs to be held and kept from rubbing through, there's a few different tools you can use to keep it managed. Cable ties, insulated cable clamps, and what i use; adhesive cable clips. If you do decide to use cable ties, be sure to use the black ties, they have a UV coating in the plastic that stop deteriorating in the sun.

Tie downs, i personally use super clamps, but there are home made options. Aluminum tubing with an exaggerated wing nut. Ratchet Straps, whatever it may be, test your method, and check it within the first half hour of your trip. Double check your tie down locations before a trip out.

Traction, one of the most common things I've seen where people get hurt, embarrassed, or just bruise your ego, is slipping on the deck, at the end of a day you often come back to the truck beat, a fresh layer of snow on the deck, and you have to climb around up on top to tie your sled down, and to get down. It's a dangerous task, make sure you have a source of traction. I have superglides on my deck, they offer a good track for your ski's to follow up the ramp, and on the deck. Helps prevent side to side movement. There is other options, I have found that traction tape doesn't do a darn thing when there's any kind of snow on top of it.

Wire types, i use an outdoor speaker wire, an insulated, high flex, 2 conductor with a nylon strip for strength. It's round, offers a visually appealing finish, and will flex in the cold.

Under deck lighting, this is a must for a sled deck, we are always loading, unloading, and using our decks in the dark,it's always a good idea to have lights under your deck.

Reflective tape, not used very often, but reflective tape is a good idea to put on the corners of the deck. Good for visibility when you don't have the clearance lights on, i know first hand, bonked my head a few times on the wheels on my deck, so i put high reflective strips on them, haven't had a problem since!

Having the proper power source to power your clearance lights and not having the plug hanging down to your hitch, or perhaps you are towing a trailer and need to plug your trailer lights into the hitch socket. You can find for your truck a 5th wheel wiring harness. I put one on my truck, put the plug behind the wheel well on the drivers side so i could reach it from the back. They are affordable, and very effective!

But that's all i have the patients for. I'll get some pictures of my deck tomorrow in the day light when it's not 60 mile and hour winds and rain out. Here's what i have so far of my deck.

I bought my sled deck used and a base model and did quite a bit to it since i've gotten it. Put on folding size extensions, all the lighting, welded seams, superglides, superclamps, supertracs, under deck lighting, grommets, wiring, and a winch.

First thing i do when putting the deck on, is make sure the deck is as far forward as possible, make sure it is safely forward as possible in other words it wont touch your back window when the truck flexes. If you deck has a headache rack, USE IT! Save your window and possibly the cab of your truck!

Second is if it's held down with turnbuckles, you tighten them in a crisscross pattern like the lug nuts of a car. Measure to make sure it's evenly spaced in your box from side to side. If your turnbuckles don't have jam nuts on them, put some on, set your tension, then tighten the jam nuts to hold the turnbuckle in place and prevent loosening.

If your deck has independent legs, like the Denali decks, it's well worth it to take some 2x4's cut them to length to tightly fit in between the front legs, and between the legs and the box. This will help with stress on the deck, and prevent cracking. I know it was a problem on some of the denali's and thats what i did with my old deck.

For clearance lights, i personally run LED's in everything. I won't run anything but. They last for ever, draw less amps, and don't run into heat problems. I run these 3/4" penny lights, i bought mine from princess auto for ease of getting new lights. If something does happen i can just go back and get another.

Wire gauge, this is something often over looked. If you are rewiring your deck, or building your own. Make sure you are running a large enough gauge of wire. You need to over estimate your distance, and over estimate your amp draw. Here's a table that will help you decide. Don't just get by on your wiring, it could burn down your whole truck.

For grommets, i run something totally different, i use 3/4" pipe end caps, everything on my deck is tubing, so i run my wires inside and hide them away keep everything neat and tidy. So i drill a 5/8" hole, and ram a 3/4" plug, drill out the center so my wire fits in it tight. These work great for thicker gauge steel or aluminum, and give a clean finish to the eye.

Your electrical wire needs to be held and kept from rubbing through, there's a few different tools you can use to keep it managed. Cable ties, insulated cable clamps, and what i use; adhesive cable clips. If you do decide to use cable ties, be sure to use the black ties, they have a UV coating in the plastic that stop deteriorating in the sun.

Tie downs, i personally use super clamps, but there are home made options. Aluminum tubing with an exaggerated wing nut. Ratchet Straps, whatever it may be, test your method, and check it within the first half hour of your trip. Double check your tie down locations before a trip out.

Traction, one of the most common things I've seen where people get hurt, embarrassed, or just bruise your ego, is slipping on the deck, at the end of a day you often come back to the truck beat, a fresh layer of snow on the deck, and you have to climb around up on top to tie your sled down, and to get down. It's a dangerous task, make sure you have a source of traction. I have superglides on my deck, they offer a good track for your ski's to follow up the ramp, and on the deck. Helps prevent side to side movement. There is other options, I have found that traction tape doesn't do a darn thing when there's any kind of snow on top of it.

Wire types, i use an outdoor speaker wire, an insulated, high flex, 2 conductor with a nylon strip for strength. It's round, offers a visually appealing finish, and will flex in the cold.

Under deck lighting, this is a must for a sled deck, we are always loading, unloading, and using our decks in the dark,it's always a good idea to have lights under your deck.

Reflective tape, not used very often, but reflective tape is a good idea to put on the corners of the deck. Good for visibility when you don't have the clearance lights on, i know first hand, bonked my head a few times on the wheels on my deck, so i put high reflective strips on them, haven't had a problem since!

Having the proper power source to power your clearance lights and not having the plug hanging down to your hitch, or perhaps you are towing a trailer and need to plug your trailer lights into the hitch socket. You can find for your truck a 5th wheel wiring harness. I put one on my truck, put the plug behind the wheel well on the drivers side so i could reach it from the back. They are affordable, and very effective!

But that's all i have the patients for. I'll get some pictures of my deck tomorrow in the day light when it's not 60 mile and hour winds and rain out. Here's what i have so far of my deck.

Last edited: