- Thread starter

- #201

Turblue

Active VIP Member

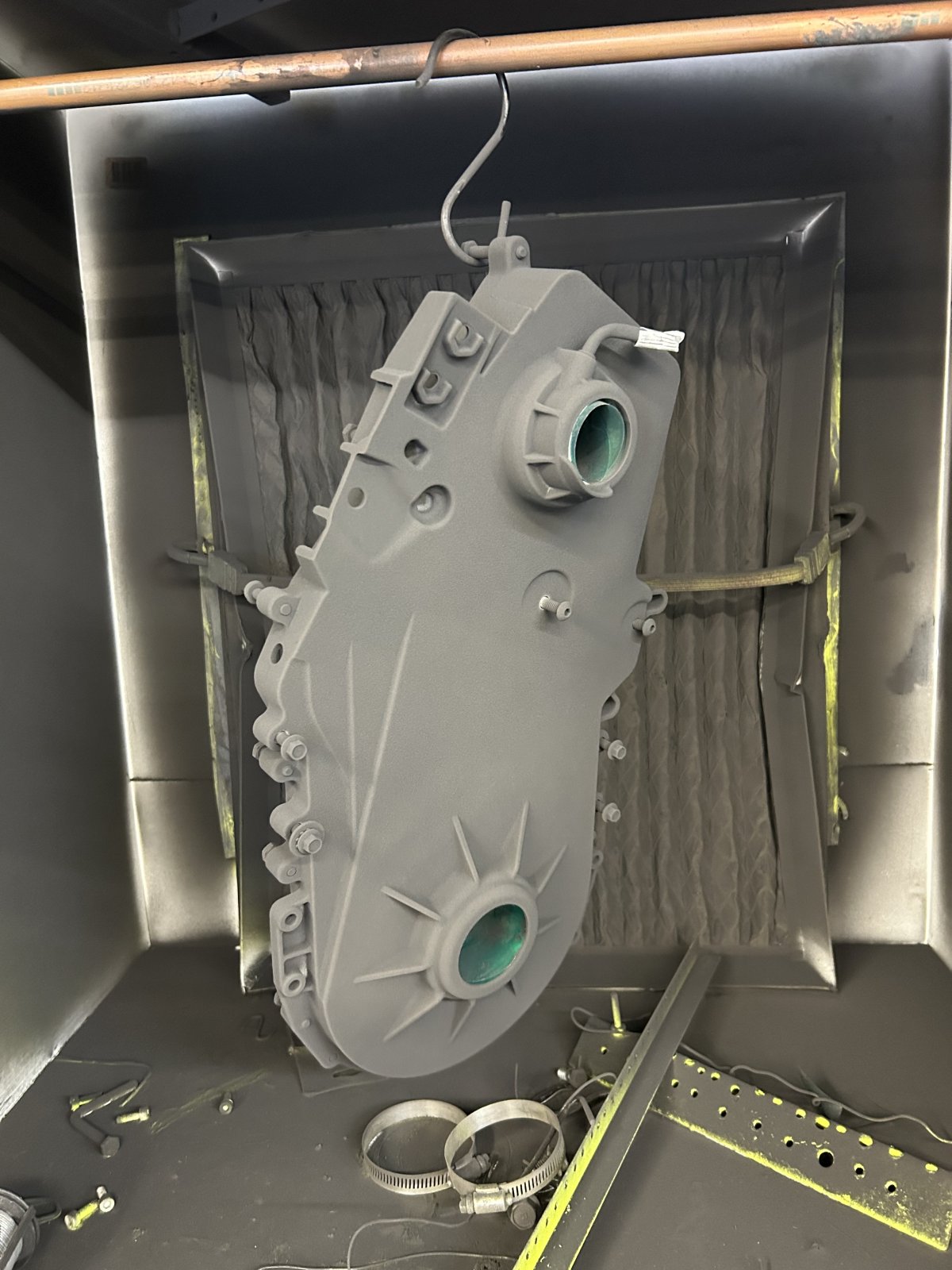

Put a real thin coat on. Turned out great.

I have a brand new jackshaft if yours is beat up. Will let it go for $100.Getting deep now. Figured since the jack shaft needs to come out might was well powder coat the inner case half black. Definitely some trickery to get that out.

Bearing on the jack shaft secondary side was toast. Hmmm only 800 miles on the sled.

View attachment 274808View attachment 274810

Thanks , but I believe the belt drive kit comes with a new jack shaft.

It’s called ocd. Lol. I bought a used 15 t3 xm summit back in the day. Cleaned up nice. Top gun in Calgary ceramic coated the pipe and y. I powdered the heat shields hi temp black.Its going to look too good, you’re not going to want to ride it LOL.

Put a real thin coat on. Turned out great.

View attachment 274812View attachment 274813View attachment 274814

Ya I see that with yours, interestingly enough I have never had that issue with any of my Cats or Yamahas or any of my sleds (Doo's).

I think it maybe the previous owner way.

It may had been trailered or even carried on a deck without any protection. Many do that, they are more then willing to pay retarded amount of coin on a sled and cheap out on protecting it during travel.

I travel a lot to ride and can tell you that well over 50% of sleds on decks are unprotected. Yup, 2 sleds 40-50k worth of toys going down the highway at 100+km/hr on salt cover roads meeting highway rigs, now thats never going to happen LOL. The salt is in the air constantly, generally my covers last about 2 maybe 3 season before they are ROTTED not torn. Wonder why that is.

Just tracking some of the history of the sled. Think it sat outside at a dealership at one point.Ya I see that with yours, interestingly enough I have never had that issue with any of my Cats or Yamahas or any of my sleds (Doo's).

I think it maybe the previous owner way.

It may had been trailered or even carried on a deck without any protection. Many do that, they are more then willing to pay retarded amount of coin on a sled and cheap out on protecting it during travel.

I travel a lot to ride and can tell you that well over 50% of sleds on decks are unprotected. Yup, 2 sleds 40-50k worth of toys going down the highway at 100+km/hr on salt cover roads meeting highway rigs, now thats never going to happen LOL. The salt is in the air constantly, generally my covers last about 2 maybe 3 season before they are ROTTED not torn. Wonder why that is.

You bet. It was getting to expensive to get parts done the way I wanted so I started doing it around 2008.Are you powder coating that at home? Looks good, maybe i missed it, but whats your setup look like? I know you.need an oven, but do you spray that on or?

I have a bunch of stuff to coat, and might be easier than bringing it some where.

Thanks. You know I’ve done lots of rails and never had an issue.Thats a setup, nice.

Just don't do your rails, bad idea, though some do. Its not advisable, seen plenty of issues with powder coated rails.