You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

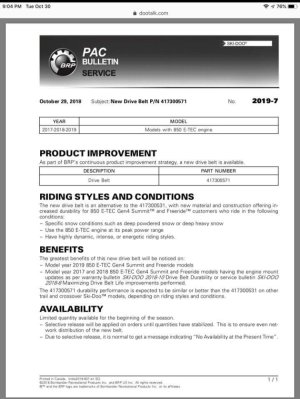

850 Summit Belt Pac Bulletin

- Thread starter Ramjet15x

- Start date

powpowpowpow

Active VIP Member

So 3rd season, belt revision number THREE, shims all around vanes added to primary and secondary, cold air duct, gearing updates. Can't wait to hear what season 4 updates will be.

powpowpowpow

Active VIP Member

HA HA I wouldn't put it past the crappy engineers to do that

pfi572

Active VIP Member

Mind blowing really ??

Anyone ever wonder how Yamaha can do it ?

Think about this for a minute?? Lol

Huge power and tracks and no trouble . Hmmmm

Anyone ever wonder how Yamaha can do it ?

Think about this for a minute?? Lol

Huge power and tracks and no trouble . Hmmmm

Rene G

Active VIP Member

Mind blowing really ??

Anyone ever wonder how Yamaha can do it ?

Think about this for a minute?? Lol

Huge power and tracks and no trouble . Hmmmm

They don’t have a wobble? That could be the answer.

powpowpowpow

Active VIP Member

Its not the wobble.

pfi572

Active VIP Member

They don’t have a wobble? That could be the answer.

The wobble is in BRP’s engineering department?

Its embarrassing really . Lol

Caper11

Active VIP Member

I have the 571 belts on my 850, don’t worry its just a belt, the 391, 531 were good belts too.

My buddy is running a 391 on his 19 turbo BTW.

My buddy is running a 391 on his 19 turbo BTW.

skegpro

Active VIP Member

.....

Caper11

Active VIP Member

Lol hey look at that, it didn’t blow.

kanedog

Active VIP Member

- Joined

- Feb 3, 2015

- Messages

- 3,142

- Reaction score

- 8,636

Kanedog's belief-

1. Belt is slipping on the primary. Black mark is occuring on/near the "hump."(VSA-variable sheave angle.)

Solution-take out the hump in the both Primary AND secondary. It's dumb.

2. Belt is being gripped on only 60% of the belt. Notice the belt wear pattern toward the inside of belt. Sheave angles do not match the belt angles therefore maximum contact between the belt and sheave cannot be achieved.

More problems occur in a harder belt compound and the problem is exacerbated as the belt won't "squish" as much. Add more clutch weight and now the durometer of the rubber is being exceeded, belt slips.

Solution-change sheave angles.

3. Belt making extreme heat due to highway gears in mountains.

Solution- Change gears to 19/53. 19/51 gearz reduce clutch temps from 220 to 190 and minimize rpm fluctuation. Do not exceed 102kmh max speed with 19/53. Had Brp used 19/51 from the beginning, a loss of more than $30,000,000(factory retool, lost customers)over time would not have occured.

Or Do like Doo......make crooked sheave, add weight, change weights, cut a hole in belt guard, add primary fins, change gearing minimally, change motor mounts, add secondary fins, change primary clutch spring, add a vent and then change belt construction three different times, make customer pay for improvements.

Except for a gear change, none of the above will help anything if a sheave is crooked.

I wouldn't even care to waste my clutch brain time on this but most of my sled friends ride 850doo and they deserve to ride worry free. Come on Doo, get this fixed. What you are doing is not working. You are over thinking this, losing customers and losing money.

Use my recommendations, call it product improvement, product refinement, claim it as "new and improved," claim it as your own idea, whatever. Just fix it.

Peace out and love thy sled.

1. Belt is slipping on the primary. Black mark is occuring on/near the "hump."(VSA-variable sheave angle.)

Solution-take out the hump in the both Primary AND secondary. It's dumb.

2. Belt is being gripped on only 60% of the belt. Notice the belt wear pattern toward the inside of belt. Sheave angles do not match the belt angles therefore maximum contact between the belt and sheave cannot be achieved.

More problems occur in a harder belt compound and the problem is exacerbated as the belt won't "squish" as much. Add more clutch weight and now the durometer of the rubber is being exceeded, belt slips.

Solution-change sheave angles.

3. Belt making extreme heat due to highway gears in mountains.

Solution- Change gears to 19/53. 19/51 gearz reduce clutch temps from 220 to 190 and minimize rpm fluctuation. Do not exceed 102kmh max speed with 19/53. Had Brp used 19/51 from the beginning, a loss of more than $30,000,000(factory retool, lost customers)over time would not have occured.

Or Do like Doo......make crooked sheave, add weight, change weights, cut a hole in belt guard, add primary fins, change gearing minimally, change motor mounts, add secondary fins, change primary clutch spring, add a vent and then change belt construction three different times, make customer pay for improvements.

Except for a gear change, none of the above will help anything if a sheave is crooked.

I wouldn't even care to waste my clutch brain time on this but most of my sled friends ride 850doo and they deserve to ride worry free. Come on Doo, get this fixed. What you are doing is not working. You are over thinking this, losing customers and losing money.

Use my recommendations, call it product improvement, product refinement, claim it as "new and improved," claim it as your own idea, whatever. Just fix it.

Peace out and love thy sled.

Last edited:

kanedog

Active VIP Member

- Joined

- Feb 3, 2015

- Messages

- 3,142

- Reaction score

- 8,636

400kmSo is this the first wrecked belt on a 2019? How many km did it make?

drew562

Active VIP Member

I’m glad I didn’t try another newer belt spitter. My 18 made me want to sled less than a hangover could. The doo850 will get beat up bad by polaris and cat this year. Save belt with Low gears = ****ty ground speed. The alpha should run hills 15 mph faster and on one belt all season.

I’m glad I didn’t try another newer belt spitter. My 18 made me want to sled less than a hangover could. The doo850 will get beat up bad by polaris and cat this year. Save belt with Low gears = ****ty ground speed. The alpha should run hills 15 mph faster and on one belt all season.

First trip to the hills will be Dec 15 to take the Alpha out.

If my brother or cousin pop a belt I am gonna so razz their azzes.

kanedog

Active VIP Member

- Joined

- Feb 3, 2015

- Messages

- 3,142

- Reaction score

- 8,636

That is incorrect info. If the sled doesn't go better with low gears, you haven't went far enuff with the gear change.

This is for mountain sledding only tho. If sledding on trails or flatland that's a different story. Actually, flatland low gears will smoke higher gears if done right but that's another subject.

Unfortunately, it's either a mountain sled or a trail sled gearing wise. You can't have both.

Peace and love.

This is for mountain sledding only tho. If sledding on trails or flatland that's a different story. Actually, flatland low gears will smoke higher gears if done right but that's another subject.

Unfortunately, it's either a mountain sled or a trail sled gearing wise. You can't have both.

Peace and love.

Last edited:

Kanedog's belief-

1. Belt is slipping on the primary. Black mark is occuring on/near the "hump."(VSA-variable sheave angle.)

Solution-take out the hump in the both Primary AND secondary. It's dumb.

2. Belt is being gripped on only 60% of the belt. Notice the belt wear pattern toward the inside of belt. Sheave angles do not match the belt angles therefore maximum contact between the belt and sheave cannot be achieved.

More problems occur in a harder belt compound and the problem is exacerbated as the belt won't "squish" as much. Add more clutch weight and now the durometer of the rubber is being exceeded, belt slips.

Solution-change sheave angles.

3. Belt making extreme heat due to highway gears in mountains.

Solution- Change gears to 19/53. 19/51 gearz reduce clutch temps from 220 to 190 and minimize rpm fluctuation. Do not exceed 102kmh max speed with 19/53. Had Brp run 19/51 from the beginning, a loss of more than $30,000,000(factory retool, lost customers)over time would not have occured.

Or Do like Doo......make crooked sheave, add weight, change weights, cut a hole in belt guard, add primary fins, change motor mounts, add secondary fins, change primary clutch spring, add a vent and then change belt construction three different times, make customer pay for improvements.

Except for a gear change, none of the above will help anything if a sheave is crooked.

I wouldn't even care but most of my sled friends ride 850doo and they deserve to ride worry free. Come on Doo. It's not that hard. You're over thinking this.

Peace out and love thy sled.

//uploads.tapatalk-cdn.com/20181119/918c808e617a6aa3de004a2bef905972.jpg

Looking at the pic, the belt contact looks more like 61.5%. You're looking at your screen at a bad angle.

Rotax_Kid

Active VIP Member

Kanedog's belief-

1. Belt is slipping on the primary. Black mark is occuring on/near the "hump."(VSA-variable sheave angle.)

Solution-take out the hump in the both Primary AND secondary. It's dumb.

2. Belt is being gripped on only 60% of the belt. Notice the belt wear pattern toward the inside of belt. Sheave angles do not match the belt angles therefore maximum contact between the belt and sheave cannot be achieved.

More problems occur in a harder belt compound and the problem is exacerbated as the belt won't "squish" as much. Add more clutch weight and now the durometer of the rubber is being exceeded, belt slips.

Solution-change sheave angles.

3. Belt making extreme heat due to highway gears in mountains.

Solution- Change gears to 19/53. 19/51 gearz reduce clutch temps from 220 to 190 and minimize rpm fluctuation. Do not exceed 102kmh max speed with 19/53. Had Brp used 19/51 from the beginning, a loss of more than $30,000,000(factory retool, lost customers)over time would not have occured.

Or Do like Doo......make crooked sheave, add weight, change weights, cut a hole in belt guard, add primary fins, change motor mounts, add secondary fins, change primary clutch spring, add a vent and then change belt construction three different times, make customer pay for improvements.

Except for a gear change, none of the above will help anything if a sheave is crooked.

I wouldn't even care to waste my clutch brain time on this but most of my sled friends ride 850doo and they deserve to ride worry free. Come on Doo, get this fixed. What you are doing is not working. You are over thinking this, losing customers and losing money.

Peace out and love thy sled.

//uploads.tapatalk-cdn.com/20181119/918c808e617a6aa3de004a2bef905972.jpg

RK's belief...

You can't keep a motor mounted on a tripod straight no matter whether you do the above or anything else. You need a 4th mount...

Similar threads

- Replies

- 15

- Views

- 3K

sprinkled with

sprinkled with  doused with

doused with .

.