tundra twin track

Active VIP Member

I farm at Westlock Alberta ride custom built TUNDRA 2-174's x 10" x 2.5 flippers with 800 rotax mounted on the tunnel above the tracks.Ride in Valemont & Blue River.

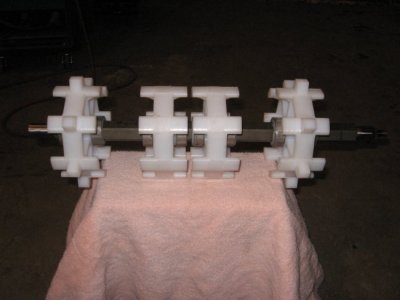

I’m posting some pictures on a deep snow mountain machine I built and designed over the last two years. My goal was to build a machine with deep snow crawl ability in trees and with a larger footprint, but with keeping the machine as short as possible, shorter than a 151 summit rev, it weighs 550 wet , the tank 5 ½ gal. 800 HO rotax,TRA, TEAM sec., 06 arctic cat wide track chain case, jackshaft & axle, Polaris 166 rails, Yamaha running board heat exchangers, ‘06 ski-doo tundra A arms, hood & panels . Pipe was built by Neil’s Power Pipes in Edmonton, Alta., 174 x 15x 2.5 tracks with consecutive serial # from Tracks Canada after cutting they are 10” wide. The tracks miss the skis by 1/2” giving the machine an overall length 122”. The machine turns on a dime and is very easy to side hill and it will go straight up as well! I will be building the rear engine panels this month after 800 hours and lots of head scratching, got 10 days on it in BC interior last winter. The pictures are as the project progressed. I’d like to thank all the people who had any input in this project, whether it is big or small.

I’m posting some pictures on a deep snow mountain machine I built and designed over the last two years. My goal was to build a machine with deep snow crawl ability in trees and with a larger footprint, but with keeping the machine as short as possible, shorter than a 151 summit rev, it weighs 550 wet , the tank 5 ½ gal. 800 HO rotax,TRA, TEAM sec., 06 arctic cat wide track chain case, jackshaft & axle, Polaris 166 rails, Yamaha running board heat exchangers, ‘06 ski-doo tundra A arms, hood & panels . Pipe was built by Neil’s Power Pipes in Edmonton, Alta., 174 x 15x 2.5 tracks with consecutive serial # from Tracks Canada after cutting they are 10” wide. The tracks miss the skis by 1/2” giving the machine an overall length 122”. The machine turns on a dime and is very easy to side hill and it will go straight up as well! I will be building the rear engine panels this month after 800 hours and lots of head scratching, got 10 days on it in BC interior last winter. The pictures are as the project progressed. I’d like to thank all the people who had any input in this project, whether it is big or small.

:d

:d