Stg2Suby

Active VIP Member

I'm new to Arctic Cat and recently bought a 2009 M8 with 600 miles total on it, 300 of those miles with 8psi boost. During the first shakedown ride I was concerned with the slop in the DD gearbox so took it apart for inspection.

Turns out the slop was normal and not in the gear mesh but rather caused by the clearances involved in the 2 floating carriers that hold the planetary gearset assembly.

What was alarming was the small bearing on the end of the shaft beside the sun gear was on it's way out The balls were still intact and bearing was turning in a crunchy fashion, but half the cage was destroyed and the metal bits floating in the case.

The balls were still intact and bearing was turning in a crunchy fashion, but half the cage was destroyed and the metal bits floating in the case.

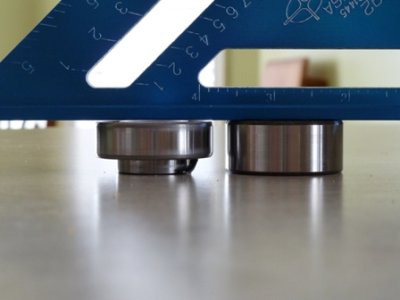

Did lots of research on this and sounds like this may be a 2009 specific problem where they used a single row bearing with a spacer where they should have used a double row bearing. Very strange the shaft is machined perfectly for the double row bearing

The solution is really basic, just buy a 5203 (3203 similar) double row bearing and press it on. The 5203/3203 is about 0.016" wider than stock bearing + spacer but this causes no issue. In fact BDX says the slightly wider bearing improves the overall assembly when it tightens up the shaft clearances a bit.

BDX sells the wide bearing upgrade or you can get one at a local bearing shop. The 3203 is same as 5303 except more angular ball/race contact for better thrust capacity. I got a high quality INA 3203-2RS from Commercial Bearing for about $30.

Overall the job is pretty basic if you're comfortable taking a chaincase / gearbox off a sled. Nothing special in rebuilding the DD regarding clearances, etc. and the only special tools are a puller and press to re/re the bearing on the shaft. I didn't have the pitman-arm style puller but Echo Cycle popped the bearing off for free

Obviously having a turbo on the sled may have caused/accelerated this failure but I'm hearing a lot of stock 2009's have had this bearing go out. Not only is the OEM bearing small to start with but it's low-quality and it sees bending moment where it's located in the assembly.

I'll post all the photos below without trying to explain every detail - feel free to ask specific questions

Turns out the slop was normal and not in the gear mesh but rather caused by the clearances involved in the 2 floating carriers that hold the planetary gearset assembly.

What was alarming was the small bearing on the end of the shaft beside the sun gear was on it's way out

Did lots of research on this and sounds like this may be a 2009 specific problem where they used a single row bearing with a spacer where they should have used a double row bearing. Very strange the shaft is machined perfectly for the double row bearing

The solution is really basic, just buy a 5203 (3203 similar) double row bearing and press it on. The 5203/3203 is about 0.016" wider than stock bearing + spacer but this causes no issue. In fact BDX says the slightly wider bearing improves the overall assembly when it tightens up the shaft clearances a bit.

BDX sells the wide bearing upgrade or you can get one at a local bearing shop. The 3203 is same as 5303 except more angular ball/race contact for better thrust capacity. I got a high quality INA 3203-2RS from Commercial Bearing for about $30.

Overall the job is pretty basic if you're comfortable taking a chaincase / gearbox off a sled. Nothing special in rebuilding the DD regarding clearances, etc. and the only special tools are a puller and press to re/re the bearing on the shaft. I didn't have the pitman-arm style puller but Echo Cycle popped the bearing off for free

Obviously having a turbo on the sled may have caused/accelerated this failure but I'm hearing a lot of stock 2009's have had this bearing go out. Not only is the OEM bearing small to start with but it's low-quality and it sees bending moment where it's located in the assembly.

I'll post all the photos below without trying to explain every detail - feel free to ask specific questions